Dallas/Fort Worth International Airport

Million Passengers in 2015

Largest Airport in The World

Contractor

Phillips/May Corporation

Architect

Corgan & Associates

Completion Date

March 2016, On-time

Scope

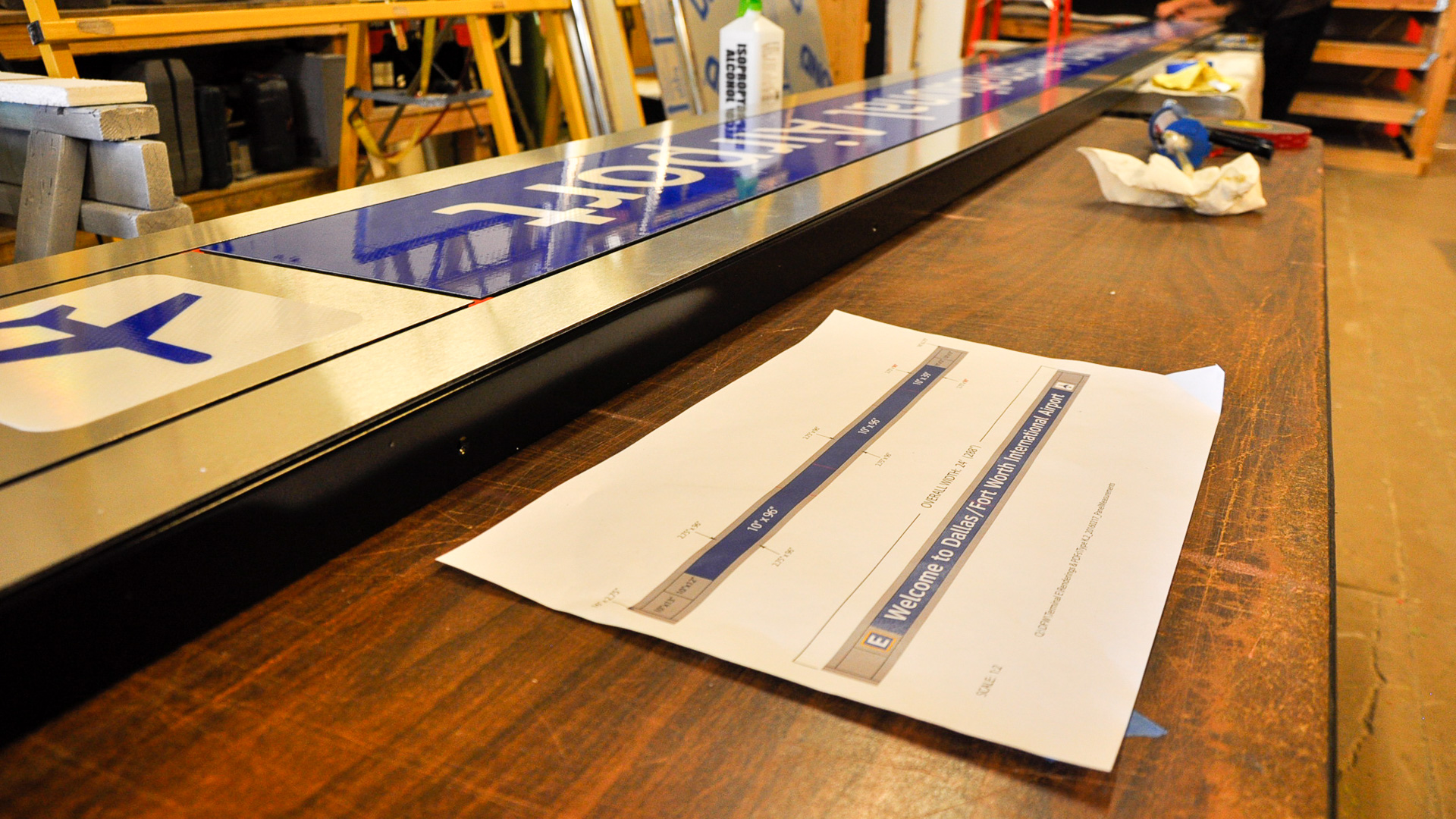

All signage for Terminal E, Phase Three, covering 7 major airline gates; approximately 50,000 sq. ft. of floor space. Custom designed LED wayfinding signs, ADA compliant room signs, and collateral signs. Scheduled in 6 sequences.

Project Descriptions

Dallas-Fort Worth International Airport is the 10th largest airport in the world and the 4th largest in the US providing service to nearly 60 million passengers in 2015. CSB was selected as the subcontractor to Phillips/May Corporation (PMC) to fabricate and install interior and exterior signage and wayfinding for Phase 3 of the Terminal E-Renewal and Improvement Program project at the Dallas-Fort Worth International Airport. Terminal E is one of the busiest terminals at DFW.

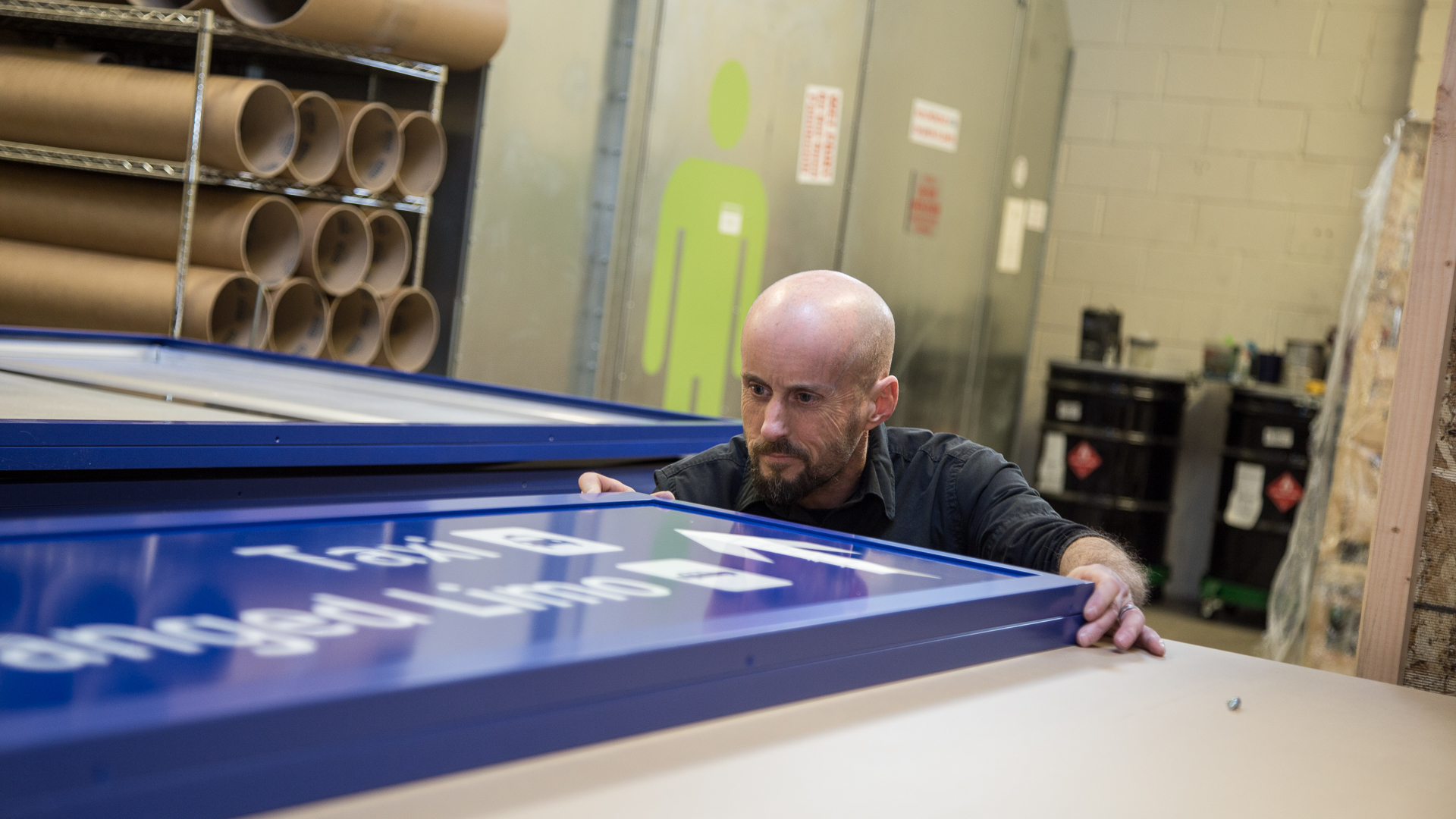

While the project included ADA room signs, a major feature of the project were the custom LED suspended and podium sign cabinets. These LED illuminated signs will significantly reduce the airport’s electricity costs as well as provide a contemporary design where the static messages could still be easily updatable for this busy, ever changing airport.

Challenges

- The airport’s sign standard had already been implemented in portions of Terminal A and B, so CSB had to fabricate signs to match the existing signage standards. However, we soon noticed many issues with the original design and through prototyping recommended several changes to the airport team that made the signs more durable and more aesthetically pleasing. For example, we developed a sign that allowed for easy sign panel changes without using a proprietary hinge and a better frame color that matched the vinyl message panel.

- Scheduling and Logistics proved to be very challenging as weather had delayed work and the deadline could not move. We were able to overcome the schedule challenges by working closely with PMC and other subcontractors to be sure sequential subcontractor work was complete so that our portion of the work could be installed next. This sequencing schedule at the end of each phase was critical. The signs needed to be installed timely and not too early so as to avoid damage from other working subcontractors.

- Lack of staging and storage areas within the active construction area meant that CSB had to carefully move only the number of units it could install in a work day to the site. CSB worked closely with PMC to establish staging and storage locations at or near our immediate work area. In addition, we had to coordinate with other subcontractors who were dealing with the same issues so as to not affect their workflow, all while providing a safe work environment, free of clutter and trash.

- Delivery constraints made on-time delivery of our fabricated signs challenging as the laydown yard was on the secure side of the airport on the tarmac. Driving a vehicle on the tarmac meant we had to coordinate with PMC to ensure the properly badged escorts were available. PMC was very busy, and communication/follow-up for scheduling these escorts was critical. We were able to accept deliveries in the least intrusive manner avoiding delays or complications.

CSB was able to provide quality craftsmanship and effective problem solving to ensure the best quality product was delivered and installed on time and under budget.